Overview

A novel nuclear power plant that will float eight or more miles out to sea promises to be safer, cheaper, and easier to deploy than today’s land-based plants. In a concept developed by MIT researchers, the floating plant combines two well-established technologies—a nuclear reactor and a deep-sea oil platform. It is built and decommissioned in a shipyard, saving time and money at both ends of its life. Once deployed, it is situated in relatively deep water well away from coastal populations, linked to land only by an underwater power transmission line. At the specified depth, the seawater protects the plant from earthquakes and tsunamis and can serve as an infinite source of cooling water in case of emergency—no pumping needed. An analysis of potential markets has identified many sites worldwide with physical and economic conditions suitable for deployment of a floating plant.

Many experts cite nuclear power as a critical component of a low-carbon energy future. Nuclear plants are steady, reliable sources of large amounts of power; they run on inexpensive and abundant fuel; and they emit no carbon dioxide (CO2).

“More than 70 new nuclear reactors are now under construction, but that’s not nearly enough to make a strong dent in CO2 emissions worldwide,” says Jacopo Buongiorno, professor of nuclear science and engineering (NSE). “So the question is, why aren’t we building more?”

The Offshore Floating Nuclear Plant

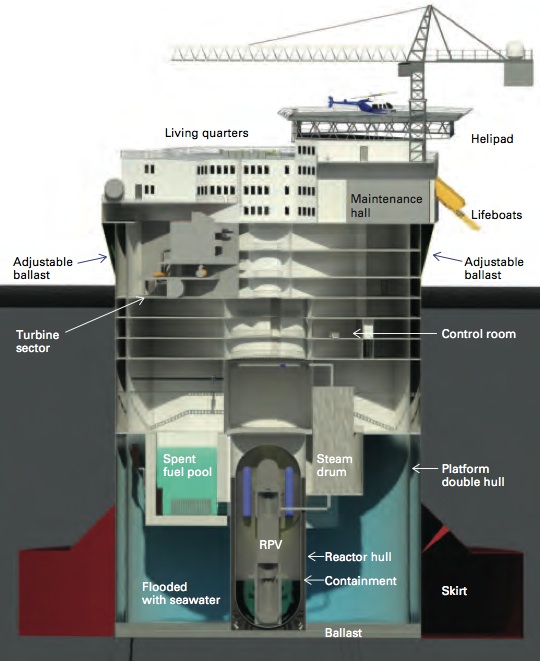

This illustration shows the researchers’ vision of the Offshore Floating Nuclear Plant. In this design, the structure is about 45 meters in diameter, and the plant will generate 300 MW of electricity. An alternative design for a 1,100 MW plant calls for a structure about 75 meters in diameter. In both cases, the structures include living quarters and helipads for transporting personnel—just as offshore oil drilling platforms do.

He cites several challenges. First, while the fuel is cheap, building a nuclear plant is a long and expensive process often beset by delays and uncertainties. Second, siting any new power plant is difficult. Land near sources of cooling water is valuable as residential property, and local objection to construction may be strenuous. And third, the public in several important countries has lost confidence in nuclear power. Many people still clearly remember the 2011 accident at the Fukushima nuclear complex in Japan, when an earthquake created a tsunami that inundated the facility. Power to the cooling pumps was cut, fuel in the reactor cores melted, radiation leaked out, and more than 100,000 people were evacuated from the region.

In light of such concerns, Buongiorno and his team—Michael Golay, professor of NSE; Neil Todreas, the KEPCO Professor of Nuclear Science and Engineering and Mechanical Engineering; and their NSE and mechanical engineering students—have been investigating a novel idea: mounting a conventional nuclear reactor on a floating platform similar to those used in offshore oil and gas drilling, and mooring it about 10 miles out to sea.

The Offshore Floating Nuclear Plant (OFNP) integrates two well-established technologies with already robust global supply chains. “There are shipyards that build large cylindrical platforms of the type we need and companies that build nuclear reactors of the type we need,” says Buongiorno. “So we’re just combining those two. In my opinion, that’s a big advantage.” By sticking with known technologies, the researchers are minimizing costly and time-consuming development tasks and licensing procedures. Yet they are making changes they think could revolutionize the nuclear option.

Advantages of shipyard construction, offshore siting

According to the researchers’ plan, OFNPs will be built entirely in shipyards, many of which already regularly deal with both oil and gas platforms and large nuclear-powered vessels. The OFNP structure (platform and all) will be built upright on movable skids, loaded onto a transportation ship, and carried out to its site. There, it will be floated off the ship, moored to the seafloor, and connected to the onshore power grid by an underwater power transmission cable. At the end of its life, it will be towed back to the shipyard to be decommissioned—just as nuclear-powered submarines and aircraft carriers are now.

Compared to deploying terrestrial nuclear plants, this process should provide enhanced quality control, standardization, and efficiency. There’s no need to transport personnel, materials, and heavy equipment to a building site—or to clean up after the plant has been retired. The plan also reduces the need for site evaluation and preparation, which contribute uncertainty and delays. Finally, the OFNP is made mostly of steel, with virtually no need to deal with structural concrete, which— according to Buongiorno—is typically responsible for significant cost overruns and construction delays as well as the emission of substantial quantities of CO2. Taken together, these factors mean that the OFNP can be deployed with unprecedented speed—an important benefit for a project that is highly capital-intensive. “You don’t want tohave a large investment lingering out there for eight or ten years without starting to generate electricity,” says Buongiorno.

The planned site of the floating plant offers other benefits. The OFNP will be situated eight to 12 miles offshore—within the limit of territorial waters—and in water at least 100 meters deep. Thus, it will be far from coastal populations (its only onshore presence will be a small switchyard and a staff and materials management facility), and the deep water beneath it will reduce threats from earthquakes and tsunamis: At that depth, the water absorbs any motion of the ocean floor during earthquakes, and tsunami waves are small. Tsunamis become large and destructive only when they hit the shallow water at the coastline—a concern for nuclear plants built on the shore.

Finally, the open ocean will provide the OFNP with an endless supply of cooling water. If accident conditions arise, seawater can be used to remove heat from the reactor: Because the plant is well below the water line, the necessary flows will occur passively, without any pumping and without any seawater contamination. “We won’t lose the ultimate heat sink,” says Buongiorno. “The decay heat, which is generated by the nuclear fuel even after the reactor is shut down, can be removed indefinitely.”

The OFNP thus addresses the three main takeaways from Fukushima cited by Buongiorno: Stay away from dense populations, protect against earthquakes and tsunamis, and never lose cooling to the fuel.

Designed for efficient operation, enhanced safety

The illustration above presents a view of the OFNP in its ocean setting. The cutaway diagram below shows the plant’s key features. The overall structure is upright, cylindrical in shape, and divided into many floors, most of them split into compartments separated by watertight bulkheads. The upper levels house noncritical components such as the living quarters and a helipad. As on oil and gas platforms, workers are brought out by boat or helicopter for three- or four-week shifts. Food, fuel, and equipment and materials for minor maintenance activities are brought out by supply boat, and heavy loads are lifted off by crane.

Details of the Offshore Floating Nuclear Plant design

This cutaway view shows key features of the OFNP. The nuclear reactor and related safety systems are located in watertight compartments deep in the structure. The reactor pressure vessel (RPV) is inside a containment structure, which is itself inside a dry compartment surrounded by seawater—a passive, continuous source of cooling when needed. Steam from steam generators immersed in the heated water inside the RPV passes to electricity-generating turbines located higher in the structure. Every 12 to 48 months, spent fuel assemblies are lifted up through the opening above the containment, and fresh fuel is inserted into the reactor. The removed assemblies are transferred to the spent fuel pool, which contains freshwater, is passively cooled by seawater, and has storage capacity to handle all the fuel removed from the plant over its lifetime. Diagram: Jake Jurewicz G

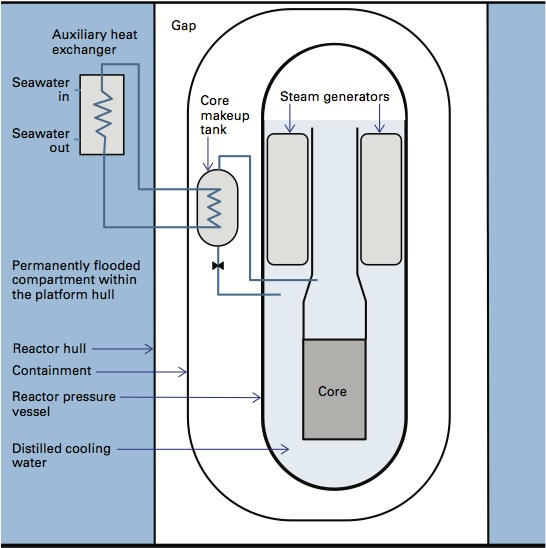

OFNP decay heat removal system

This diagram shows the reactor core and steam generators immersed in fresh, distilled cooling water inside the reactor pressure vessel (RPV). If operation of the cooling pumps is interrupted, the cooling water can flow passively though an auxiliary heat exchanger immersed in seawater. If a more serious problem such as a pipe break occurs, the cooling water is released from inside the RPV into the containment structure, and seawater can be allowed to enter the normally empty space around the containment. Heat from the cooling water will pass through the containment wall to the seawater. The seawater flows naturally through the structure, so it is constantly renewed, providing an infinite source of cooling when necessary.

The nuclear reactor (either a 300 MW or a 1,100 MW unit) and its related safety systems are located in watertight compartments low in the structure to enhance security and safety, provide easy access to ocean water, and give the overall structure a low center of gravity for increased stability. The reactor core and associated critical components are housed within a reactor pressure vessel (RPV), and the RPV is located inside a compact structure called the containment. Surrounding the containment— but separated by a gap—is a large chamber that extends to the edge of the cylindrical structure and is constantly flooded with seawater, which enters and exits freely through ports.

Specific design features allow for response to various types of interruptions in normal cooling operations. Generally, pumps bring in cool water from the low ocean layers and discharge the used, heated water to the warm surface layers, thereby preventing “thermal pollution” that can threaten the local ecosystem. If that cooling process is temporarily disrupted, heated water from the reactor is allowed to circulate naturally to a special heat exchanger within the flooded chamber (see the bottom figure at left). If a more serious problem (for example, a pipe break) threatens the core, distilled cooling water from inside the RPV is released into the containment (always keeping the core submerged), and seawater from the outside compartment fills the gap around the containment. Heat is efficiently transferred through the containment wall to the seawater, which is constantly and passively renewed. At all times, the cooling water and seawater are kept separate so that contaminants cannot flow from one to the other.

In the unlikely event that—despite continuous heat removal—pressure inside the containment builds up to dangerous levels, gases from within the containment can be vented into the ocean. However, the gases would first pass through filters to capture cesium, iodine, and other radioactive materials, minimizing their release. Current research is tracking the likely dispersion and dilution of such materials to ensure that any radioactivity in the water remains below acceptable limits even under such extreme circumstances.

Promising economics, abundant potential markets

The MIT team believes that the OFNP may be “a potential game changer” as far as the economics of nuclear power is concerned. It provides the economic advantage of “factory” production of multiple units, yet the units can be large enough to benefit from economies of scale. In addition, unlike any type of terrestrial plant, the OFNP is mobile. “If you build a power plant on land, it remains at the construction location for 40 or 50 years,” says Buongiorno. “But with the OFNP, if after a decade or two you need the generating capacity 100 miles farther up the coast, you can unmoor your floating power plant and move it to the new location.”

The viability of the researchers’ idea depends, of course, on whether there are locations with the necessary physical attributes—deep water relatively near shore but away from busy shipping lanes and frequent massive storms—as well as economic and other incentives for adopting the OFNP.

A detailed analysis identified many potential sites. For example, regions of East and Southeast Asia have limited indigenous resources, a high risk for both earthquakes and tsunamis, and coastal populations in need of power. Countries in the Middle East could use OFNPs to fulfill their domestic needs, freeing up their valuable oil and gas resources for selling. Some countries in coastal Africa and South America rely on power supplied by generators running on imported diesel fuel—an expensive and highly polluting way to go. “Bringing in an OFNP, mooring it close to the coast, and setting up a small distribution system would make a lot of sense—with minimal need for infrastructure development,” says Buongiorno.

Continuing research

The researchers are continuing to work on various aspects of the OFNP. For example, they are developing optimal methods of refueling, a detailed design of the mooring system, and a more thorough model of the plant’s hydrodynamic response in storm waves. In addition, they are establishing a cohesive OFNP protection plan. The plant design provides considerable security: The reactor is deep in the structure within multiple hulls; the high upper decks permit an unimpeded 360-degree view; and the physical layout minimizes approaches for attackers. Working with security experts, the researchers are now investigating additional strategies involving state-of-the-art sonar and radar systems, submarine netting and booms, and a team of armed security guards.

While much work remains, Buongiorno says, “We anticipate that the first OFNPs could be deployed in a decade and a half—in time to assist the massive growth in nuclear energy use required to combat climate change.”

This research was supported by the MIT Research Support Committee. Further information can be found in:

J. Buongiorno, M. Golay, N. Todreas, A. Briccetti, J. Jurewicz, V. Kindfuller, D. Fadel, G. Srinivasan, R. Hannink, A. Crowle, and M. Corradini. “Offshore small modular reactor (OSMR): An innovative plant design for societally acceptable and economically attractive nuclear energy in a post-Fukushima, post-9/11 world.” Proceedings of the ASME 2014 Small Modular Reactors Symposium, Washington, DC, April 15–17, 2014.

J. Buongiorno, J. Jurewicz, M. Golay, and N. Todreas. “Light-water reactors on offshore floating platforms: Scalable and economic nuclear energy.” Paper 15366, Proceedings of ICAPP ’15, Nice, France, May 3–6, 2015.

This article appears in the Spring 2015 issue of Energy Futures.