Overview

A row housing project designed by an international, MIT-led team is demonstrating novel concepts in energy and architecture at the Internationale Bauausstellung (International Building Exhibition, or IBA) in Hamburg, Germany. Two innovations in the “Soft House” create an active architecture responsive to environmental conditions and changing homeowner needs: A solid softwood structure sequesters carbon, and a movable textile infrastructure harvests solar energy and provides solid-state lighting. On the exterior, a responsive photovoltaic (PV) textile façade adjusts to follow the sun, creating a novel two-axis solar tracking system. Inside, movable light-emitting curtains create spatial divisions and personal micro-climates. In other work, the MIT team has designed a lightweight solar canopy that can be mounted on urban rooftops, bringing renewable energy to dense urban areas.

Most people think of infrastructure for cities and buildings as fixed, permanent, and hard. Sheila Kennedy, MIT professor of the practice of architecture and a founding principal of the architectural firm KVA MATx, has a different idea. She calls it soft architecture. Two tenets are key: design that enables interaction between physical materials and digital networks, and resilient infrastructure that can adapt to new conditions over time and use multiple sources of energy that work together and interact to create new spaces and environments.

To make this vision a reality, says Kennedy, one needs to think of energy infrastructure not as a technology that is distinct from architecture but rather as a new set of materials with which architecture can be made. Kennedy and her collaborators have developed design techniques for integrating multi-junction PVs with textiles and other flexible substrates. The infrastructure that results from these materials is lightweight, bendable, and easy to transport and install, and it can be manufactured with less than half the embodied energy use and carbon emissions of glass-based PVs.

Clean manufacturing of a flexible energy infrastructure is just the first step. As with any innovation, the creative challenge is to find the unique opportunities the new renewable materials make possible—things that centralized electrical technology cannot do. “We need to have conceptual flexibility and creativity to see where the new materials can take us,” says Kennedy. “The most interesting applications for new materials are those that work at many levels. If we can demonstrate these ideas, we can get them out into the marketplace—where they can start doing good in the world—earlier than we might have thought.” And that is happening now.

Soft Cities: Retrofitting renewables in urban areas

Implementing renewable energy in rapidly growing cities and dense urban areas of the world poses many challenges. Streets are narrow; older buildings have limited structural capacity; installation must be simple; and renewables need to provide immediate and tangible benefits. With a planning grant from the MIT Energy Initiative, Kennedy enlisted a multidisciplinary MIT team to investigate how flexible thin-film organic PVs—as well as LED lighting—could be integrated into textile-based roof canopies for dense urban neighborhoods.

As a case study, the team used the historic Casa Burguesa district of Porto in Portugal. Built in the 17th century, this district has more than 25,000 row houses, each with a narrow, deep plan footprint, tall upper floors, and an interior stairwell that provides daylighting and ventilation. Rooftop solar-harvesting systems with good exposure to sunlight could help to reduce environmental strain and revitalize this urban area as a model for new urban design and energy infrastructure concepts that can be applied in many different global regions.

Architectural rendering of the solar-harvesting rooftop canopies for the Casa Burguesa district of Porto, Portugal. All images and diagrams (unless noted) are courtesy of KVA MATx.

Working closely with the Porto Faculty of Architecture (FAUP) and industrial collaborators, the MIT team designed prototypes of a rugged, easy-to-install textile PV canopy that could be mass manufactured (see image above). The design integrates the rooftop PV canopy with the vertical space of the existing stairwell, allowing the renewable technology to complement and augment the existing row house architecture.

By day, the rooftop canopy provides energy, shading, and expanded rooftop living space; at night, the lightweight solar textiles are retracted and rolled into the stairwell for storage. The vertical stairwell shaft is used to distribute a network of clean energy, which can be used to power solid-state lighting for the interior as well as the façades of the old Porto district. Building owners could get a rebate from the city government for illuminating the historic façades, and they could sell clean energy to charge electric motorcycles, providing sustainable connections from this dense urban district to Porto’s public transportation system, the Metro.

The Soft House

Drawing on their experience, Kennedy and her colleagues at KVA MATx decided to design a new model for low-carbon urban housing from the ground up. Their concept, called the Soft House, won first prize in an invited design competition for the IBA, a prestigious exhibition of innovative architectural ideas with a history that dates back to the 1920s. The IBA award confers both a great honor and an unusual opportunity: All the winning designs are being built on Wilhelmsburg Island in the River Elbe. There, 30 hectares of new housing, work, and leisure space will be monitored, visited, and ultimately occupied, becoming a 21st century model for sustainable living.

The Soft House, an innovative work/live row housing project, is now demonstrating novel concepts in energy and architecture at the IBA in Hamburg, Germany. The four housing units include a responsive energy-harvesting textile façade and movable light-emitting interior curtains that enable occupants to reconfigure their domestic space, creating a flexible new model for carbon-sequestering architecture. Each unit has a terrace space, a PV canopy, and a vertical convection atrium layer that circulates air, brings daylight into the ground floor, and creates vertical views of the sky. Photo: Sheila Kennedy, MIT

In the Soft House (shown above), Kennedy and a multidisciplinary group of KVA colleagues and collaborators demonstrate new relationships between domestic energy infrastructure, flexible living space, and smart furnishings in a responsive, soft architecture that meets Germany’s rigorous environmental standards and passive-house energy requirements.

The Soft House uses a traditional all-wood “brettstapfel” construction that relies on wood dowel joints with no glues, nails, or screws. The solid spruce wood structure is temporally “soft,” as the wood sequesters carbon. (Indeed, considering the life-cycle materials-production process, using spruce absorbs about as much carbon dioxide from the atmosphere as using reinforced concrete emits.) And the wood is fully demountable for recycling at the end of the building’s life. The wood structure can be fabricated by local carpenters or small-scale manufacturers, and it is exposed as an interior finish. This approach creates a natural character within the housing units, reduces embodied material energy, and eliminates the need for loose insulation, which is environmentally damaging. A dense wooden radiant floor linked to a geothermal source distributes cooling in the summer and heating in the winter.

The solid wood structure posed a design challenge: Without the internal cavity of a stud-framed wall, there is no open “chase space” for running electrical wires. To address this problem, the design team reconsidered the location and role of domestic electrical distribution and lighting. “Conceptually, we had to unpack a century of wall conventions in architecture,” says Kennedy. “We moved electrical distribution out of the wall into the room and integrated it with movable domestic curtains. And on the exterior, we developed a soft solar-harvesting façade, a movable energy infrastructure that establishes the public identity of the architecture.”

Façades that move, curtains that illuminate

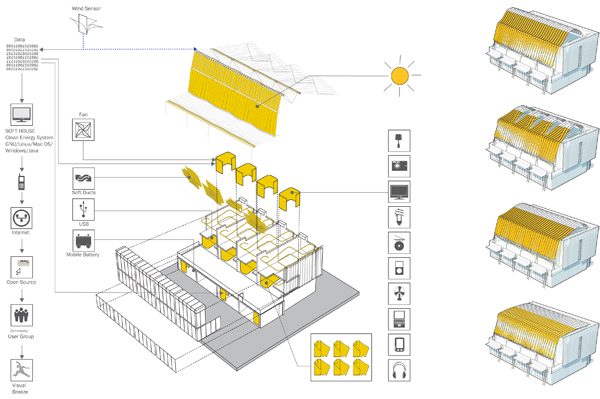

The Soft House responsive façade is the first architectural demonstration of soft, two-axis solar harvesting and tracking. The façade system—shown in the diagrams below—is made of textile strips integrated with a pliable, spring-like structure of fiber-reinforced composite boards that bend to optimize the seasonal solar angle of the flexible PVs. Daily east-west sun-tracking and daylight-harvesting are achieved with simple winch rotation, drawing on Hamburg’s local maritime industries. The strips twist to open views, create privacy, and provide shade in summer and indoor daylighting in winter. As the energy-harvesting, responsive façade system changes position, it creates different shade patterns that become part of the architecture of the house. Adjustments to the responsive façade are made seasonally and daily via the Soft House Building Management System (BMS).

Responsive energy-harvesting façade.

A pop-apart drawing of the Soft House, with the PV- and LED-embedded textile installations highlighted. The four housing units share an energy-harvesting façade with integrated flexible solar cells. As shown in the four small diagrams at the right, the individual strips of the façade change position to track the daily and seasonal movement of the sun. Top (winter): The façade is fully raised to capture lower winter sunlight, and many strips are twisted to let in sunshine. Second down (autumn): Some strips are raised and twisted. Third down (summer): The façade is lowered to capture the higher summer sun, and the strips are fully closed to provide shade. Bottom: The façade retracts flat against the roof during a storm.

The Soft House responsive façade generates about 60 kilowatt-hours (kWh) of electricity daily, or about 16 kWh per housing unit—well over half the anticipated household energy needed, with the balance coming from IBA’s supplementary clean energy grid. The façade demonstrates how historically “hard” energy infrastructure—such as nonrenewable energy, glass-based solar panels, and sun-tracking machinery—can be transformed by design that uses soft, lighter-weight, low-carbon materials linked by energy and information networks.

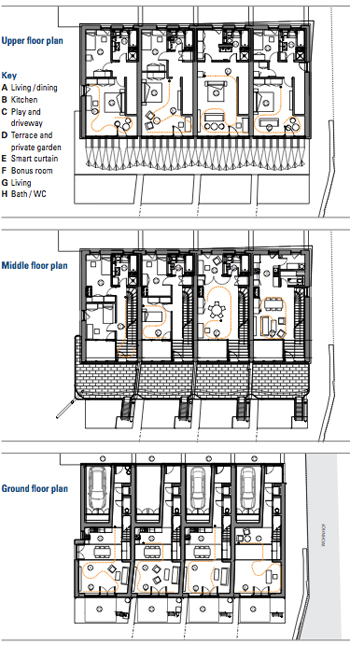

The exterior soft façade is complemented on the interior by a set of novel smart curtains made of computer-knitted textiles with reflective strips and LEDs that provide a movable layer of insulation and energy-efficient solid-state lighting. The tracks of the smart curtains distribute the Soft House renewable low-voltage DC electrical service for household electronics, radiant floor pumps, and LED lighting. By moving the curtains along the tracks, residents are able to enclose space to create temporary rooms for different activities, as shown in the diagrams below. “When you [enclose] small spaces, the reflective elements in the curtains reflect the heat from the radiant floor in winter or collect cooled air if it’s summertime, and you can create a personal microclimate,” notes Kennedy. She likens it to traditional practices of encircling beds and other furniture with textiles in order to stay warm.

Floor plan flexibility

The simple, open Soft House floor plan provides flexible space for living and working. Plumbing cores are designed to let homeowners choose the number of bedrooms and the kitchen location they prefer. A separate entry off the garden level supports work/office activities on the ground floor, and the garage space can be used as a workshop area. The light-emitting curtains—represented by the yellow lines on the floor plans—can be reconfigured to create illuminated spaces with personalized climate zones to suit the needs of the homeowners.

The Soft House BMS manages energy generation and storage, and monitors energy consumption. A wireless DC controller provides occupants with fine control of the LED smart-lighting nodes, which can be programmed using a laptop interface. The smart curtain LED lighting system allows for real-time sensing and visualization of outside climate conditions. In “Visual Breeze,” one of several programmable software settings, exterior wind speed data are represented indoors by LED lighting that moves through the Soft House curtains, creating an ambient lighting expression of the external environment. “We bring the exterior climate inside in a playful and beautiful way, reminding us that choices we make in our domestic lives are always related to the exterior climate,” says Kennedy.

With its all-wood structure and movable soft layers, the Soft House makes the thick perimeter wall used in standard German passive-house buildings unnecessary, creating instead a flexible domestic living space. And when smart curtains and tracks perform the work of the domestic infrastructure, it is easier to respond to changes in technology. “Instead of tearing down your whole house, you can simply upgrade your furnishings,” Kennedy says. “It’s a different idea about timescales in architecture, where architecture is much more permanent and the infrastructure is mobile.”

In this project, Kennedy and her team have seen the Soft House project through from design to construction, a process that brings a valuable learning experience and applied knowledge of what new flexible semiconductor materials can do. And if the real-world implementation goes as planned, the Soft House project can be replicated as a model for conditions anywhere in the world. Says Kennedy, “The real impact and excitement of the Soft House come in with the idea of what can happen with this model going forward.”

Research on the rooftop canopy for the urban row houses in Portugal was funded by a planning grant from the MIT Energy Initiative. Work on the Soft House was supported by the International Bauausstellung (Hamburg), KVA, and a consortium of international private- and public-sector collaborators. For more information, go to www.kvarch.net or to www.iba-hamburg.de/en/themes-projects/ and search on “Soft House.”

This article appears in the Spring 2013 issue of Energy Futures.